CAPABILITIES

Precision-Machining for Critical Industries

Concept Reality’s capabilities include precision-machining and manufacturing, fabrication, assembly and kitting , as well as testing. Our vertically integrated approach ensures consistent quality, faster lead times, and seamless communication across every phase of production. With advanced equipment, experienced teams, and disciplined process control, we deliver parts and assemblies that meet the most demanding aerospace, defense, energy, and semiconductor requirements. Looking for help in the design process as well? Our DFM (design for manufacturing) services will be just what you need.

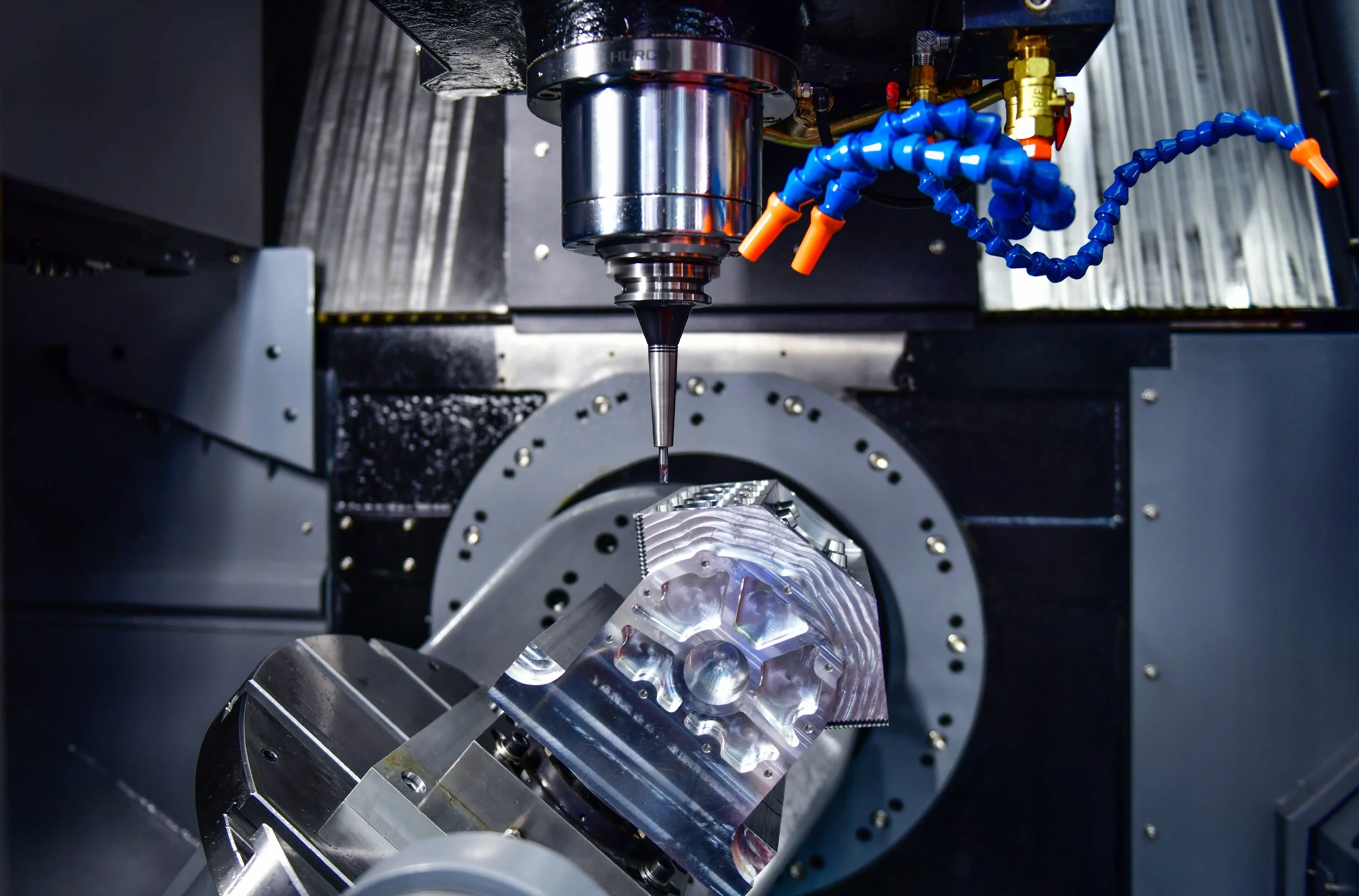

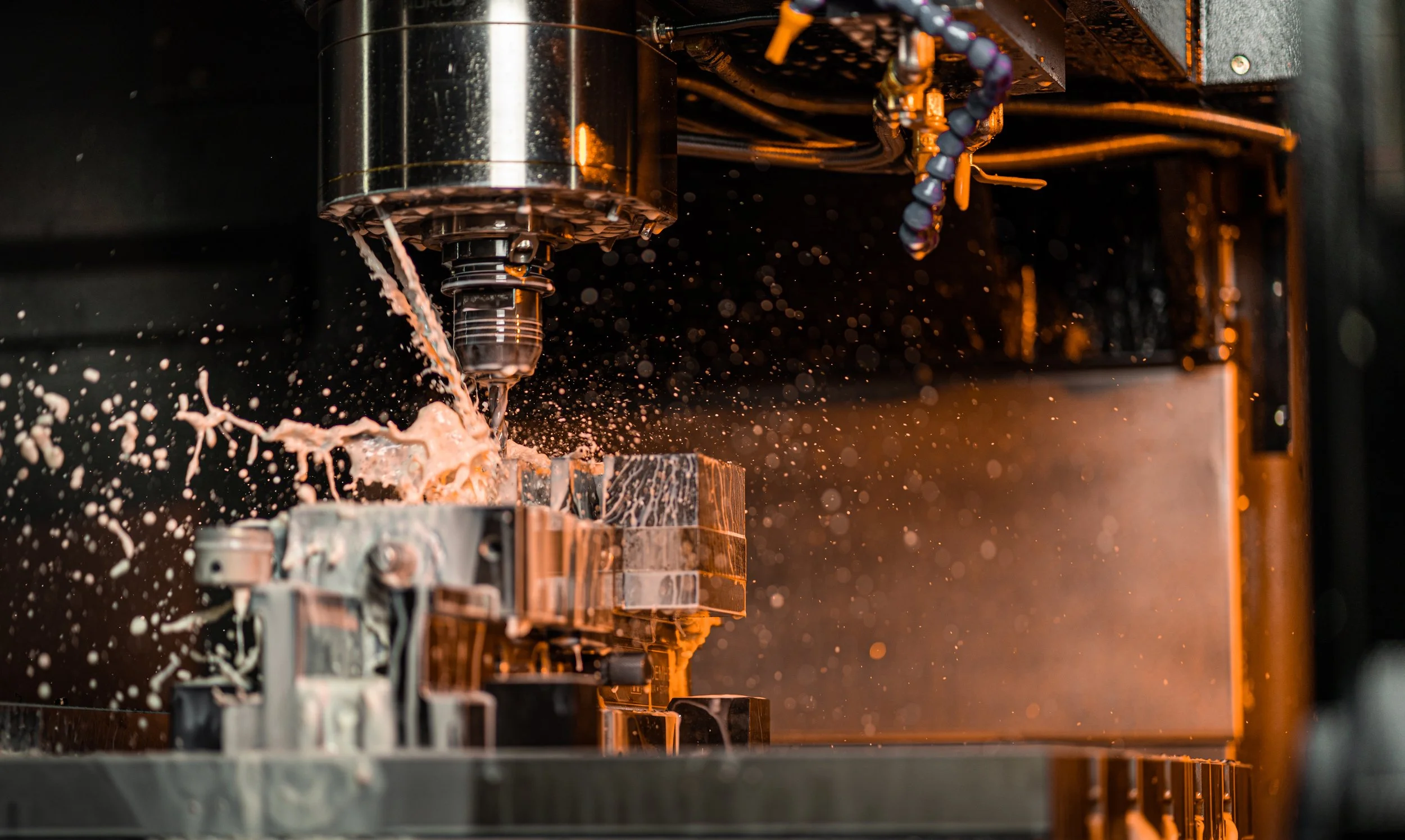

MACHINING

Tight-tolerance precision machining for critical components. We work with a wide range of materials and advanced processes including 5-axis and high-speed CNC machining to deliver accuracy, repeatability, and superior surface finishes.

COMPONENT FABRICATION

Certified component fabrication for industries where precision and predictability are essential. Our in-house engineering expertise, flexible capacity, and ISO 9001:2015 / AS9100 Rev D certifications ensure dependable results from prototype to production.

ASSEMBLY AND KITTING

Complete assembly and custom kitting solutions that streamline workflow from machined parts to install-ready systems. By managing everything under one roof, we help customers improve quality, efficiency, and lead time.

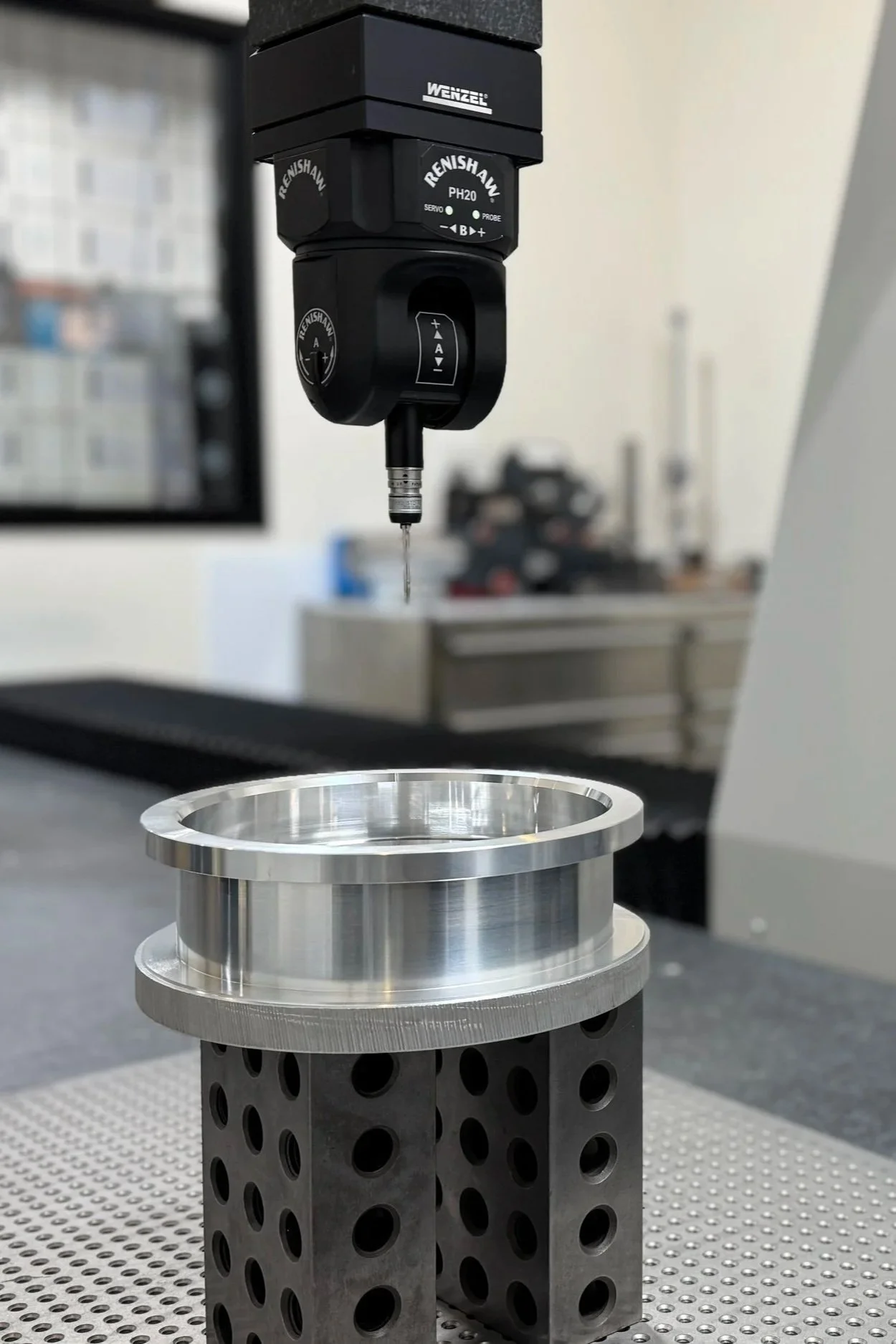

ENGINEERING AND TESTING

Tailored engineering and test programs designed to validate performance under real-world conditions. Our team performs a range of mechanical and non-destructive tests, providing detailed reports and actionable insights that drive continuous improvement.