MACHINING

PRECISION MACHINED PARTS

Concept Reality, Inc. specializes in tight tolerance precision machining for industries where precision and reliability are essential - including aerospace, defense, energy, and semiconductor. We work with a wide variety of materials including, aluminum, stainless, low carbon steel, high carbon steel, copper, brass, magnesium, titanium and plastics. Our equipment is some of the best in class, our people are highly trained with years of manufacturing and machining experience, and our customer service will exceed expectations.

“Concept has become one of our top suppliers and continuously meets or exceeds our expectations”

5-Axis CNC Machining

5-Axis CNC Machining is an advanced manufacturing process where a computer-controlled machine tool can move a cutting tool or part along five different axes simultaneously.

Why it’s important

Complex Geometry: Keen ability to produce thin-walled geometries necessary in aerospace and defense applications where intricate shapes and undercuts are required.

Precision: Eliminates multiple setups, reducing error and improving dimensional accuracy.

Tight Tolerances: We’re able to hold tight tolerances on key part features.

Efficiency: Speeds up production since parts can often be completed in a single operation. Ability to use tangent plane machining to increase productivity.

Surface Finish: Produces smoother, more consistent finishes, especially on contoured surfaces.

We program everything in-house using Hyper Mill and Mastercam.

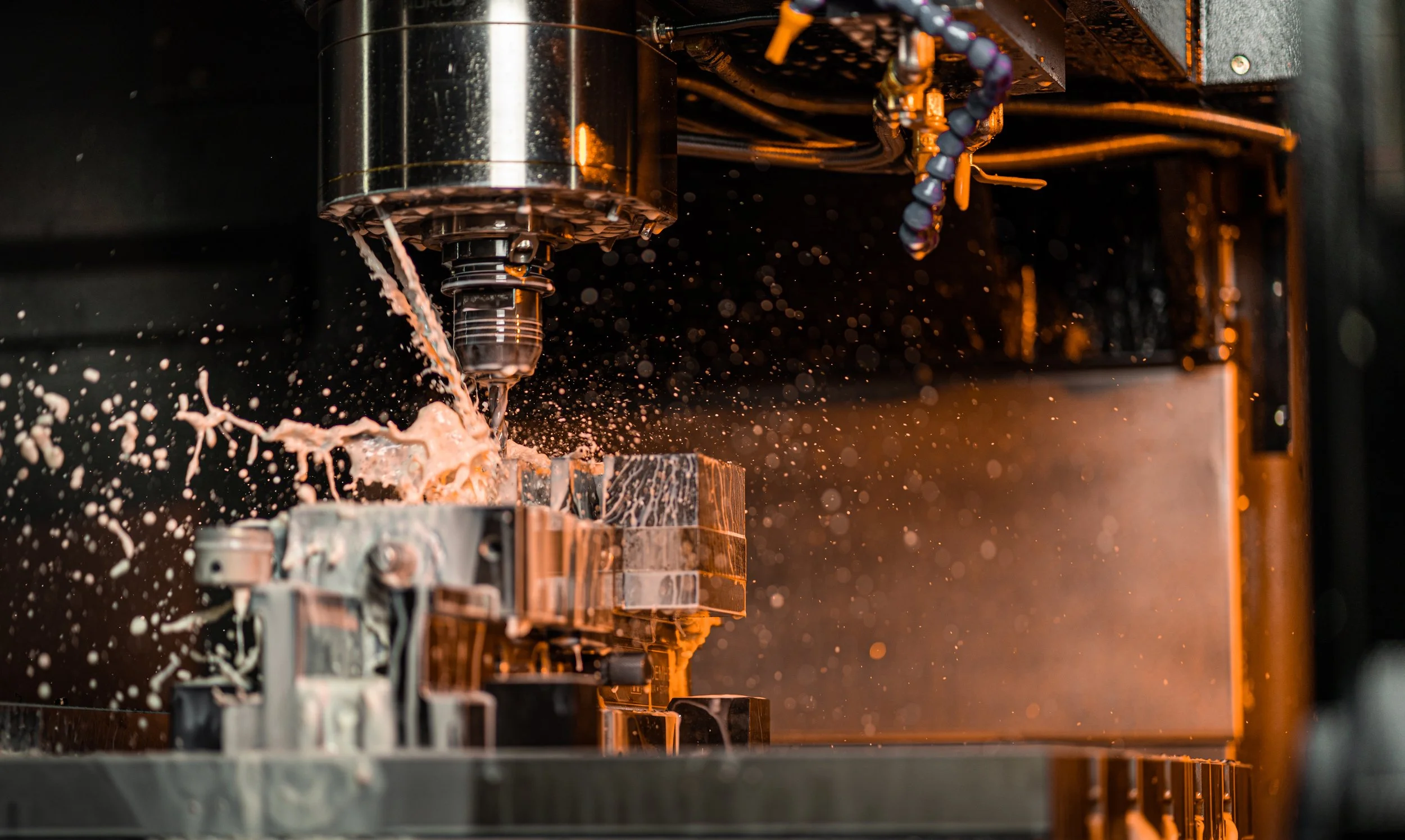

HIGH-SPEED MACHINING SOLUTIONS

High-speed CNC machining is a manufacturing process that uses computer-controlled machine tools operating at much faster spindle speeds, feed rates, and cutting speeds than conventional CNC equipment. The goal is to remove material quickly and precisely while maintaining tight tolerances and excellent surface finishes.

Why It’s Important

Faster Production – Higher cutting speeds dramatically reduce cycle times, which means projects are completed sooner.

Better Precision – The advanced controls and tooling used in high-speed CNCs allow for extremely tight tolerances, even at rapid speeds.

Superior Surface Quality – Parts often come off the machine with smoother finishes, minimizing or eliminating secondary polishing or grinding.

Cost Efficiency – Faster machining plus reduced finishing steps means lower overall production costs.

Ideal for Advanced Materials – High-speed CNCs handle aerospace alloys, titanium, stainless steels, and composites more efficiently.

In industries like aerospace, defense, and semiconductors, speed and precision aren’t just advantages, they’re requirements. High-speed CNC machining ensures that complex, mission-critical parts can be produced on time and to exact specifications.